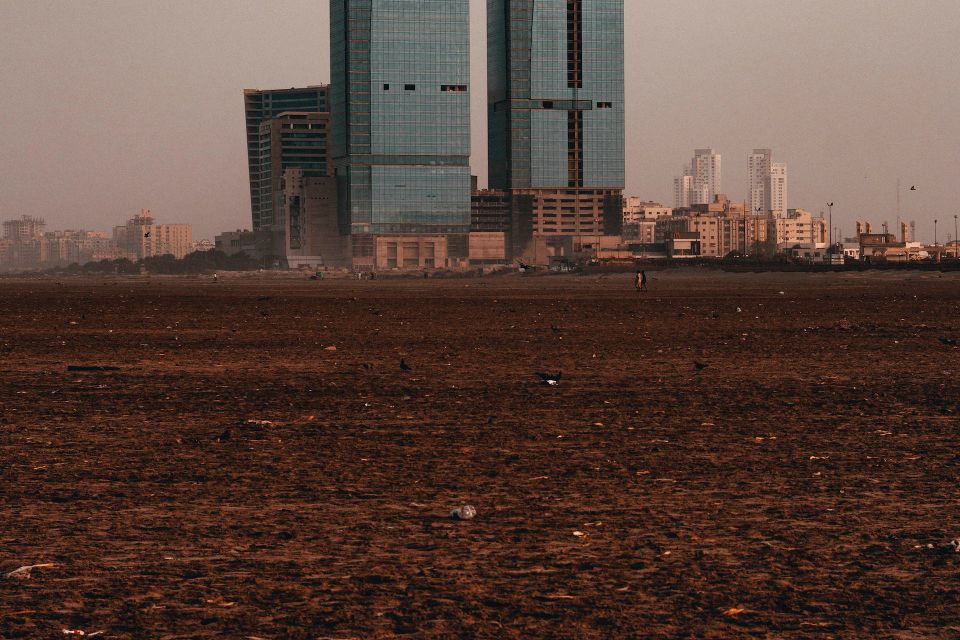

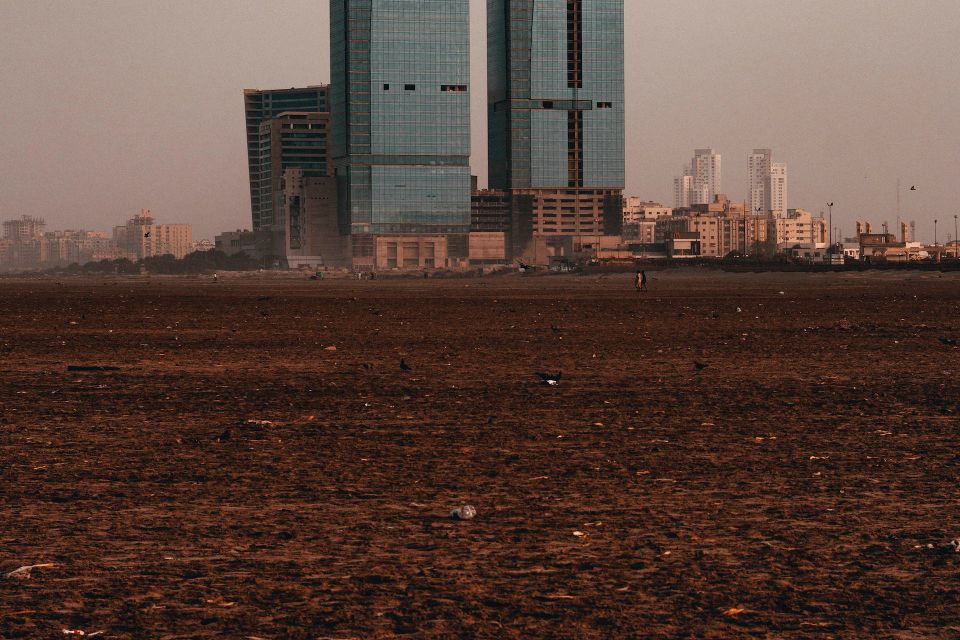

The soil condition at the construction site directly affects project timelines, costs, and overall success. One critical factor that construction professionals must consider is the moisture content of the soil. Excessive moisture can lead to delays, unstable foundations, and potential project failure. Soil Dry Down techniques can significantly enhance efficiency and set the stage for a smooth construction process by accelerating the drying process of construction site soil. These methods minimize moisture-related problems and help ensure the project stays on track.

In this in-depth article, we will explore the importance of Soil Dry Down techniques in construction projects and how they effectively impact project efficiency. By understanding how Soil Dry Down methods work and implementing them appropriately, construction professionals can avoid costly project delays, ensure a stable foundation, and enhance overall project performance. Additionally, we will provide expert tips and insights on utilizing Soil Dry Down techniques for maximum results and efficiency gains in your projects.

1. The Importance of Soil Dry Down in ConstructionExcessive soil moisture can pose a significant challenge for construction projects, causing delays, driving up costs, and potentially compromising the project's structural integrity. The importance of Soil Dry Down techniques as a solution to these challenges cannot be overstated. Implementing proper Soil Dry Down methods can:

a. Prevent Delays: Excessive soil moisture can lead to halted operations, as construction teams wait for soil to dry down naturally. Soil Dry Down techniques help avoid such delays and ensure the construction process remains on schedule.

b. Ensure Stability: Excess moisture in the soil can cause swelling, shrinking, and compromised load-bearing capacity. Soil Dry Down techniques help maintain a stable foundation to support the new infrastructure.

c. Enhance Efficiency: By implementing Soil Dry Down methods, construction professionals can save time and resources needed to mitigate moisture-related issues, resulting in a more efficient construction process.

2. Soil Dry Down Techniques and Their ApplicationsSeveral methods can be employed to expedite the drying process of construction site soils, and their selection depends on factors such as soil type, environmental conditions, and project constraints.

a. Mechanical Drying: This technique involves the use of specialized heavy equipment to turn and mix the soil, reducing compaction and increasing evaporation to remove excess moisture. Mechanical drying can be achieved through tilling, harrowing, and aeration.

b. Solar Drying: In areas with abundant sunlight, Solar Drying can be an effective option. The technique involves spreading the soil out over tarps or geotextile sheets, increasing its surface area and enabling faster, uniform evaporation of moisture.

c. Chemical Drying: Chemical Drying accelerates the drying process by altering the soil structure. Typically, this method involves adding lime, cement, or fly ash to the soil, which helps absorb and bind excess moisture and accelerate the curing process.

d. Dewatering Systems: Dewatering systems, such as pumps, wells, or trenches, can be employed to remove excess groundwater and lower the water table at the construction site. This method prevents the ingress of water into the excavated areas, ensuring a stable and dry working environment.

3. Assessing Moisture Levels for Optimal Soil Dry DownTo ensure the success of a Soil Dry Down project, it is crucial to assess the initial moisture levels accurately and monitor them throughout the drying process. Some common methods for measuring soil moisture content include:

a. Visual Inspection: Observing the color, texture, and appearance of the soil can provide valuable insights into moisture levels. However, visual inspection alone may not offer the level of accuracy needed for a comprehensive assessment.

b. Proctor Test (Standard and Modified): The Proctor Test measures how a soil's moisture content affects its compaction and ability to support the necessary loads in the construction process. This test is often performed in a laboratory, providing essential data to help select the most effective Soil Dry Down technique.

c. Field Testing: Field tests, such as the cone penetrometer test, vane shear test, or dynamic cone penetration test, help assess soil stability and moisture content on site. These tests provide data on in-situ conditions and offer a more accurate representation of the soil's characteristics.

4. Expert Tips for Successful Soil Dry Down Implementationa. Proper Planning: Effective Soil Dry Down requires thorough planning, taking into account material availability, equipment needs, personnel, and project timelines. Careful scheduling and management of resources will ensure a successful and efficient process.

b. Weather Monitoring: Be aware of weather conditions during the Soil Dry Down process, as rainfall and heavy winds can hinder drying efforts. Continuously monitoring weather forecasts will help you adjust your approach to maintain progress.

c. Test Soil Incrementally: Regularly test the moisture content of the soil throughout the drying process to ensure it reaches the desired level. This allows for quick adjustments to the method or timeline if necessary.

Building Efficient Construction Projects with Soil Dry Down TechniquesThe implementation of Soil Dry Down techniques can greatly impact construction project efficiency by reducing delays, ensuring stability, and saving time and resources. Understanding the various methods, applications, and expert tips for successful Soil Dry Down practices is crucial to achieving optimal results in your projects.

At Terra-Firma Stabilization & Reclamation, we have the expertise in Asphalt Pulverization, Soil Improvement & Modification, Soil Stabilization, and Full-Depth Reclamation that can help construction projects achieve their desired outcomes through efficient

soil dry down techniques. Let us help you unlock the full potential of your construction project while improving efficiency and ensuring long-lasting, high-quality infrastructure. Contact us today to discuss customized soil management solutions tailored to your project's needs!